Label printing dispenser - flexible and reliable labeling

PA7100 - Reliably print and directly apply labels

The PA7100 is a label printing dispenser that reliably prints and applies labels to your product in a single pass. A wide range of different applicators makes it possible to apply labels on one side, on two sides or even across corners. The PA7100 is completely controlled by electric servo motors, which allows reliable and extremely precise labeling. All settings are made via the integrated touch control panel.

One control unit - many possibilities

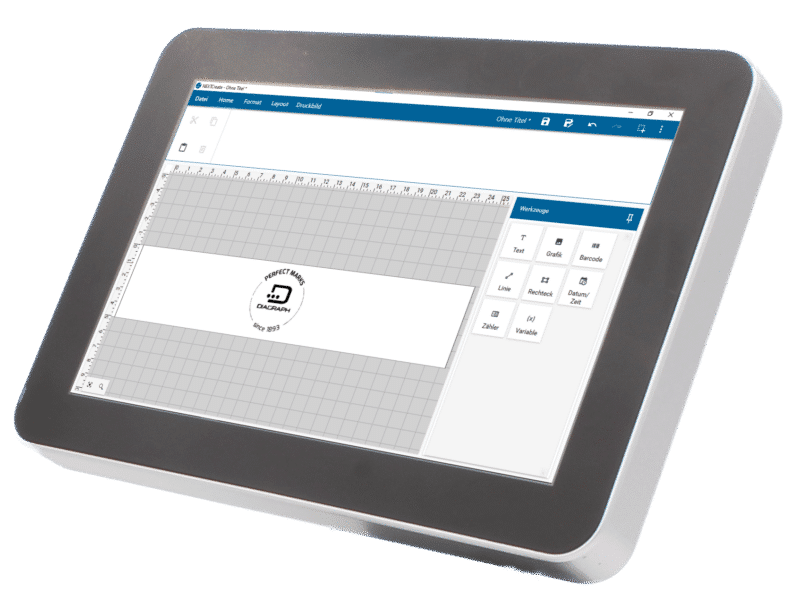

Operate your printing system via the Touch12 control. We will find a solution for your application, whether with our standard operating software or a user interface customized to your needs. This enables the connection of different printing systems and functionalities. The connection of a database or various interfaces can also be implemented.

Talk to us about the possibilities in your application.

The right dispensing arm for every application

Linear dispensing stamp - TAMP

The TAMP is the standard dispensing arm and is used very frequently. It can be used to apply labels to one side of a product. This can be the top, bottom or a side surface.

The label is applied by a linear movement. To suit your application, we offer the TAMP with different maximum strokes between 125mm and 750mm.

With the help of the integrated sensors, the TAMP can detect the product surface and automatically react to products of different sizes. This increases flexibility and reliability and reduces complexity.

The dispensing arm is driven by a servo motor. This allows large dispensing speeds, precise and repeatable positioning, and easy adjustment via the integrated touch control panel.

On two sides - FASA

This dispensing arm, which applies labels by a pivoting motion, can apply a label to any side of a product.

In addition, two labels can be dispensed on two different sides of a product. This can be done, for example, on the front and top, but other combinations are also possible.

This module is also ideally suited for dispensing longer labels across corners.

The FASA applicator is available with different arm lengths, thus achieving different ranges and cycle rates. Drive via servo motors enables high dispensing speeds and precise positioning.

On uneven objects - HST

The movable HST pad allows labels to be applied to uneven surfaces. The labels are pressed on with one side of the pad by a roller and applied to the passing product. Here, only the roller is in contact with the product, the inclination of the pad allows to compensate for unevenness.

The HAST applicator is based on the TAMP dispensing arm. Also it donates the labels through a linear movement.

Around the corner - WASA

If a label is to be applied across a corner, the WASA applicator is the solution.

The label is applied by a purely mechanical applicator. The WASA arm is positioned on the conveyor so that passing products are driven against it. An adjustable pressure force applies the label to the product across the corner.

Non-contact - BLOW

For particularly pressure-sensitive items, the BLOW dispensing system is recommended. This is a TAMP system with the special feature that the labels are not pressed on, but are blown onto the product from a short distance with a blast of air.

Product advantages

Label Print Dispenser - PA7100

What our customers say

For us, no other device came into question, we are very satisfied with the label printing dispensers from Diagraph.

Dieter Dörken, Department Manager Small Packaging, Feldsaaten Freudenberger, Krefeld, Germany

Video

25% energy savings when labeling

The use of Diagraph's PA7100 label printing dispensers has led to significant energy savings at SLG Kunststoff.

Download case study free of charge

SLG Kunststoff saves 25% energy with the label printing dispensers PA7100 from Diagraph in use 24/7

Video

Printing and dispensing labels in dusty environments

Print and donate labels "just in time".

PA7100 label printing dispensers from Diagraph allow labels to be printed and dispensed in one operation and in just the right amount. The data link to the merchandise management system prevents labeling errors.

Download case study free of charge

This is what convinced Feldsaaten Freudenberger of the PA7100 label printing dispenser

The advantages of the label print dispenser PA7100

- Simple commissioning

- High clock rates

- Sensors for process monitoring

- Reliable labeling

- Low operating costs

Frequently asked questions about labeling systems

Do you have further questions? Here you can find more details.

The PA7100 is a label printing dispenser, labels are printed and applied to their products or packaging fully automatically. By printing the labels directly in the dispensing system, you can react very flexibly to production quantities, product changes and individual labeling.

Typical applications include applying the labels directly to the product packaging, to a secondary packaging (outer carton) or marking a pallet.

Technical data

| Details | Label print dispenser PA7100 |

|---|---|

| Printing method | Thermal transfer or direct thermal printing |

| Printing system | Sato or zebra |

| Print speed | up to 406 mm/s |

| Max. Application speed | 120PPM; 90m/min |

| Print resolution | 203/305 dpi |

| Max. print area | 167mm x 355mm (width x length) |

| Min. label dimensions | 26mm x 13mm (width x length) |

| Max. Label dimensions | 167mm x 355mm (width x length) |

| Capacity of the label roll | 355mm (roller outer diameter), 76mm (core diameter) |

| Max. Ribbon length | 600mm |

| Mains connection | 100 -240 VAC; 47 – 63 Hz; 3 – 6A |

| Ambient conditions | 5 - 40°; 15 - 85 % RH; non-condensing |

| Dimensions | 787mm x 660mm x 686mm (WxHxD) |

| Weight | 55kg label print dispenser without stand |

| Applicators | E-TAMP; E-FASA; WASA; BLOW; HAST |